Are you deciding which screening media to choose to ensure accurate, productive, and stable screening under all conditions? Choosing the right screen affects not only the quality of separation but also production output, equipment longevity, and operating costs. Today, several major groups dominate the market—woven wire screens, welded mesh, perforated plates, harp screens, polyurethane and rubber modular panels, and self-cleaning high-frequency screens.

Below are the differences between all types, their typical applications, advantages, disadvantages, and selection recommendations.

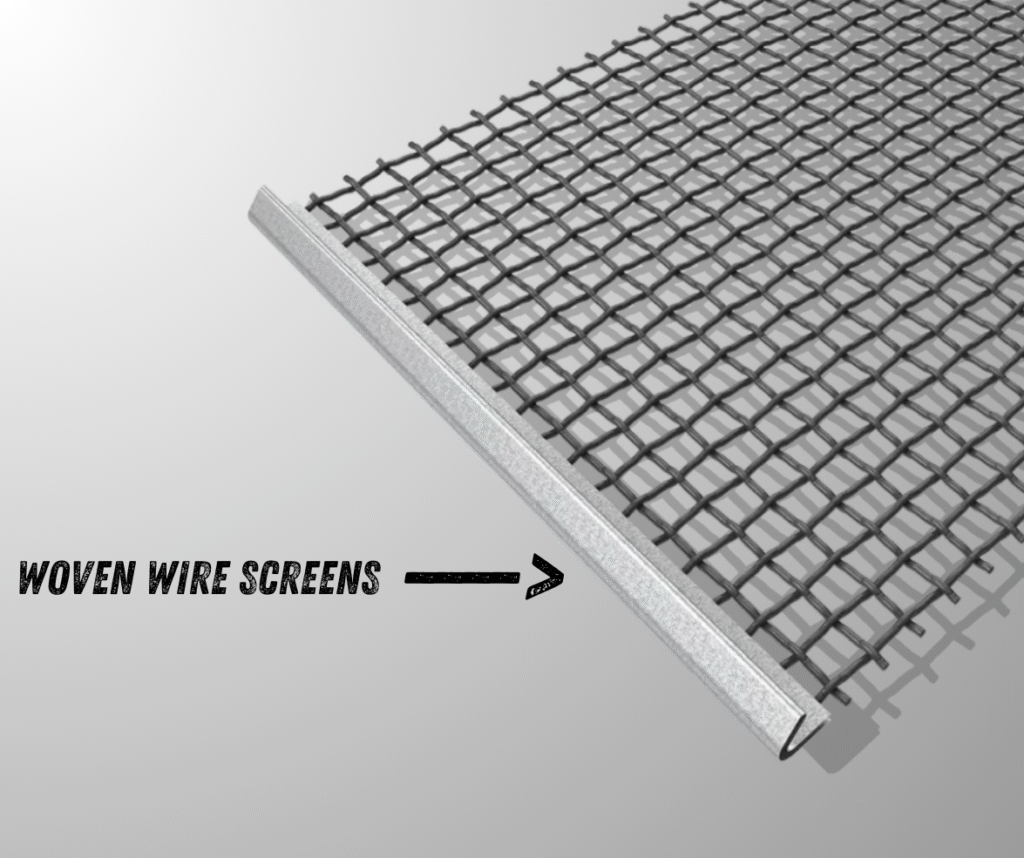

Woven Wire Screens

Where to use?

For sand, gravel, and crushed stone fractions where high open area and precise classification are required. Ideally suited for dry sand, granite aggregates, washed gravel, or fine concrete mix fractions.

Advantages:

-

Wide selection of aperture sizes and wire diameters ensures accurate classification.

-

High open area results in high screening capacity.

-

Lightweight, economical, and easy to replace.

Disadvantages:

-

Faster wear in abrasive conditions.

-

Prone to blinding and clogging in wet or clay-rich materials.

-

Lower impact resistance compared to perforated or polyurethane screens.

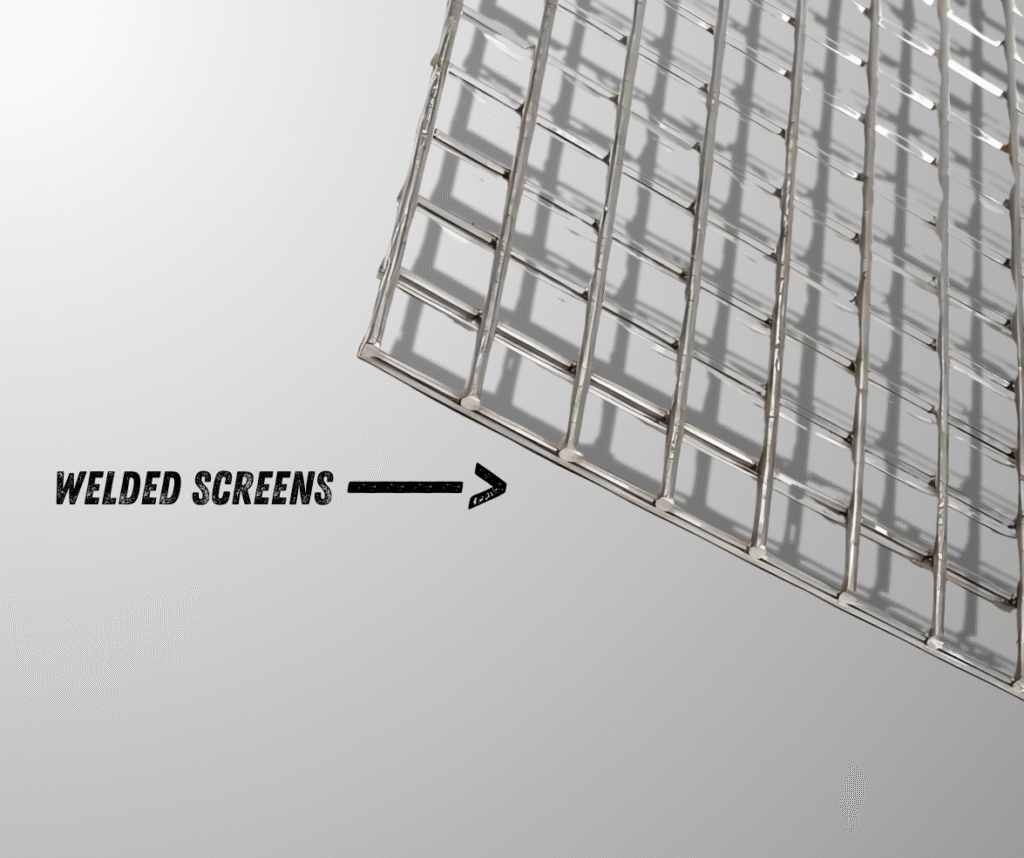

Welded Wire Screens

Where to use?

When structural rigidity is required—coarser fractions, primary screening stages, or higher load applications. Suitable for coarse aggregates, dolomite, granite, and quarry applications.

Advantages:

-

Very strong and stable aperture geometry due to rigid welded intersections.

-

Longer service life compared to woven wire under heavy loads.

-

Custom aperture geometries available.

Disadvantages:

-

Lower elasticity—more sensitive to impact loads.

-

Heavier, more difficult to install.

-

Lower open area (may reduce throughput).

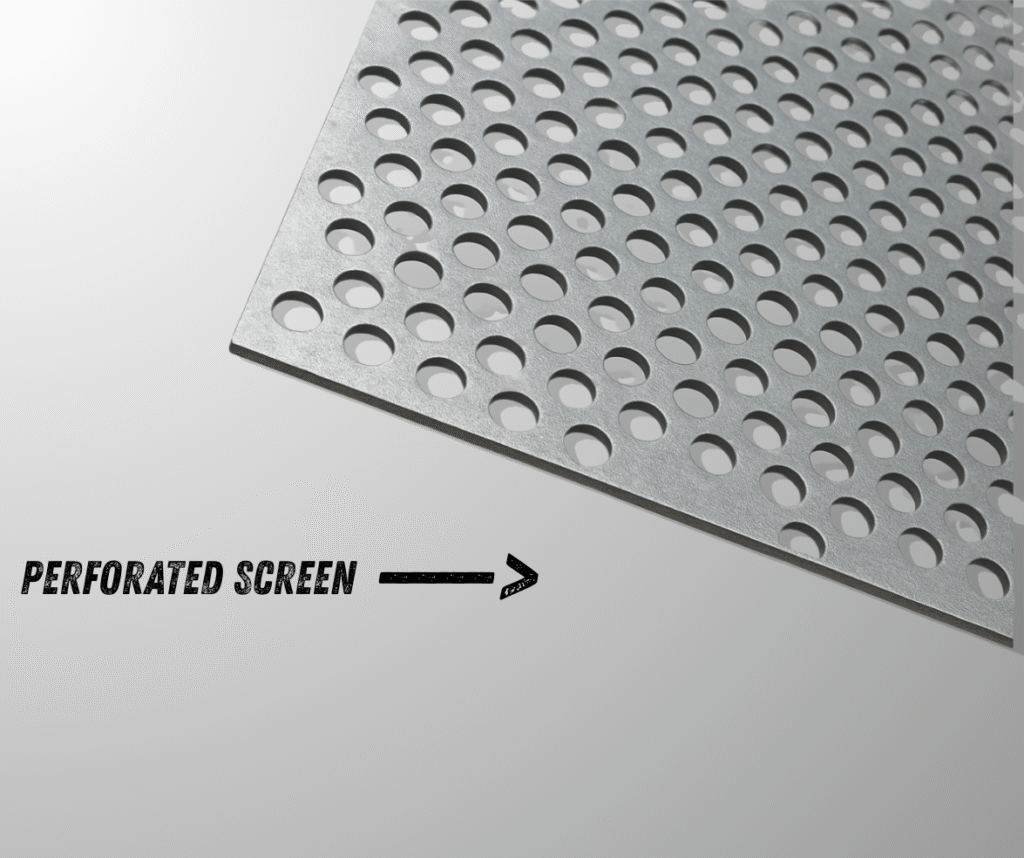

Perforated Screens

Where to use?

For primary scalping, coarse, aggressive, or sticky materials. Also ideal for asphalt plants, hot materials, or feed with clay contamination.

Advantages:

-

Solid monolithic plate—excellent impact and abrasion resistance.

-

Minimal deformation and long service life.

-

Various hole shapes available (round, square, slotted).

Disadvantages:

-

Lower open area—reduced efficiency for fine fractions.

-

Heavier weight increases load on the vibrating deck.

-

May require a larger screening area to reach the same output.

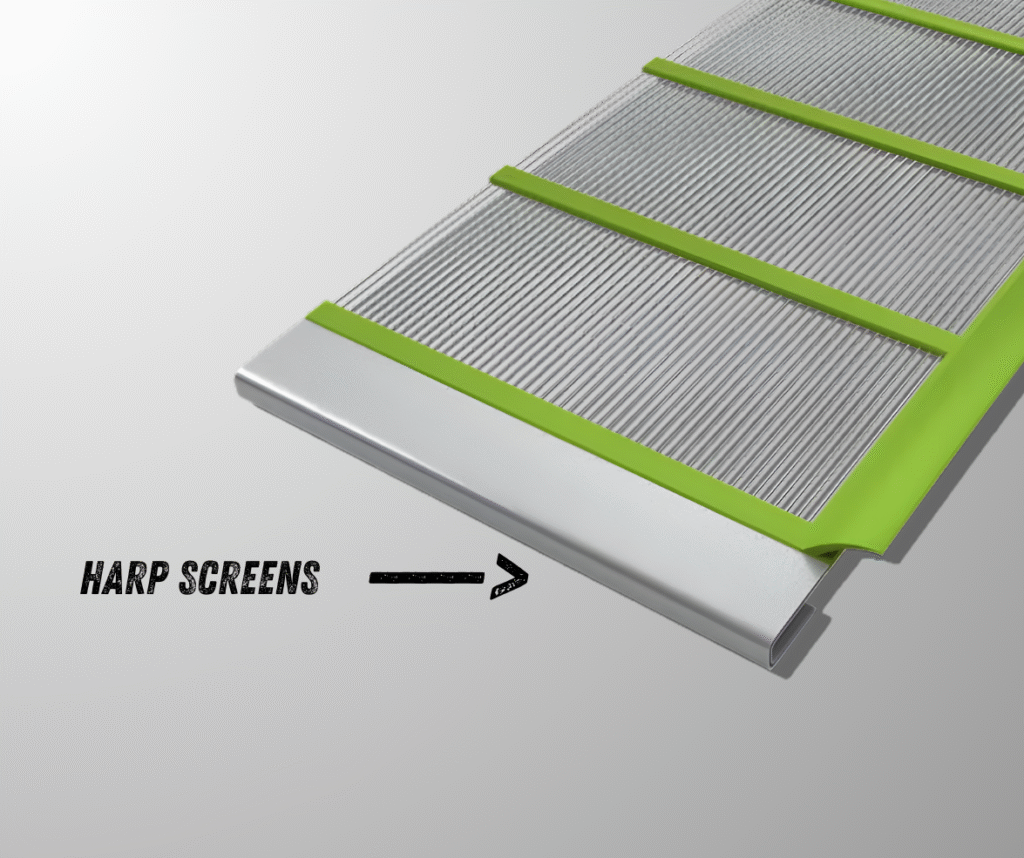

Harp (Stringer) Screens

Where to use?

Best for wet sand, clay-contaminated gravel, fine crushed stone fractions, and recycled construction materials (e.g., concrete and brick mixes).

Advantages:

-

Natural self-cleaning effect—much less blinding.

-

Very high throughput, especially with slotted apertures.

-

Quieter operation compared to rigid metal screens.

Disadvantages:

-

Limited impact resistance and low suitability for highly abrasive feed.

-

Requires correct tensioning and periodic adjustments.

-

Lower precision for extremely fine fractions.

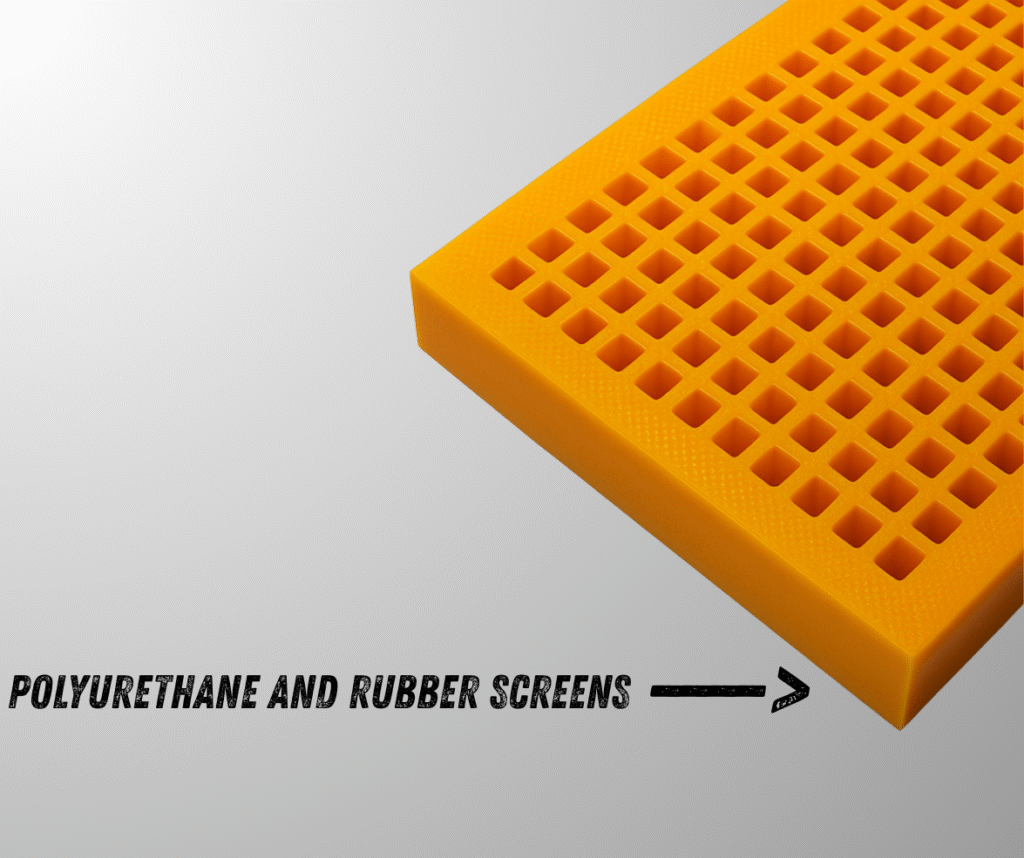

Polyurethane and Rubber Modular Screens

Where to use?

Ideal for granite, dolomite, crushed stone, concrete aggregates, and other quarry materials when lower noise, easier maintenance, and long lifespan are required.

Advantages:

-

2–5 times longer lifespan than steel wire (depending on conditions).

-

Excellent impact absorption and reduced noise.

-

Modular design—only worn sections need replacement.

Disadvantages:

-

Higher initial cost.

-

Lower open area compared to metal screens.

-

Temperature limitations (PU/rubber unsuitable for high-heat applications).

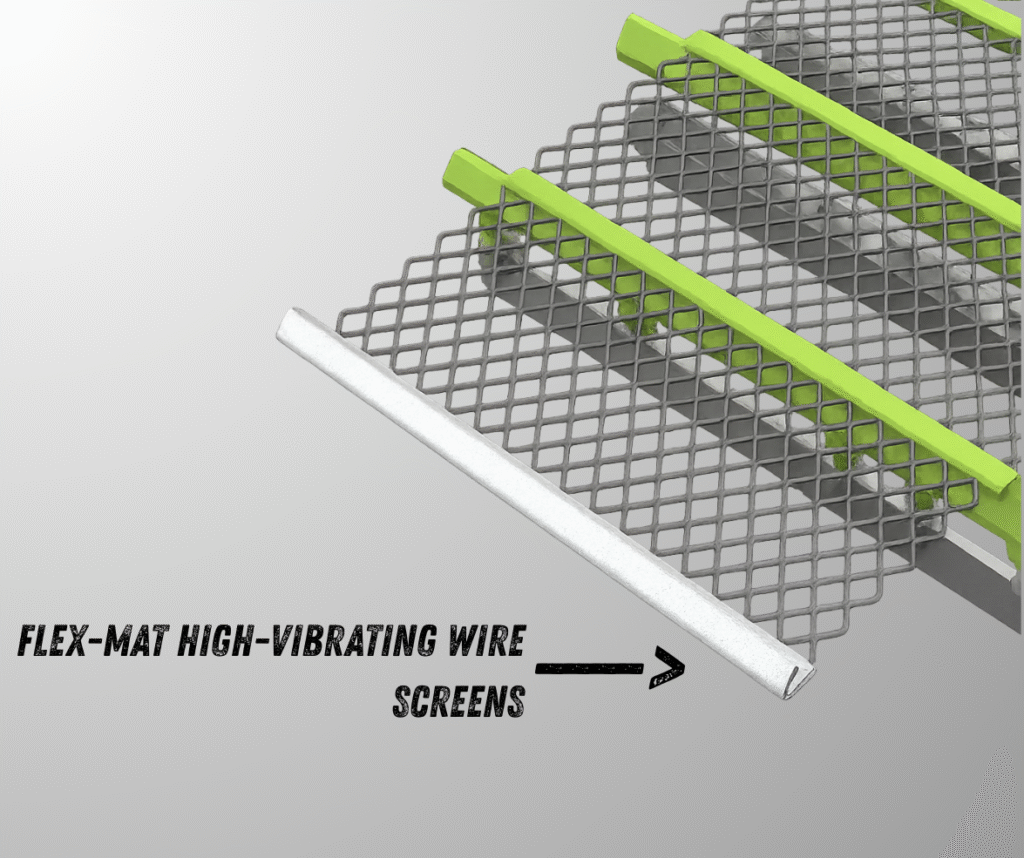

Self-Cleaning and High-Frequency Screens

Where to use?

When the feed tends to blind or output decreases due to moisture or inconsistent material structure. Suitable for wet sand, clay-rich gravel, recycled materials (concrete, brick mixes), and other problematic feeds.

Advantages:

-

Fewer shutdowns for cleaning, more consistent throughput.

-

Better real-world performance in wet conditions.

-

Special construction (flexing, elastic, or conical wires) reduces clogging and maintains efficiency.

Disadvantages:

-

More expensive than standard woven screens.

-

Not always necessary for dry, clean fractions.

New Innovative Category – High-Frequency Screens (Major Flex-Mat Active Wire)

These are next-generation self-cleaning screens based on high-frequency wire vibration.

Unlike traditional metal screens, Major Flex-Mat wires vibrate independently of the machine structure, resulting in better removal of sticky materials, higher open area efficiency, and reduced blinding.

Key Benefits:

-

Up to 40% higher throughput compared to standard screens.

-

True self-cleaning without auxiliary tools or downtime.

-

Longer service life, reduced vibration load on equipment.

-

Suitable for concrete plants, gravel pits, recycled materials, and sand washing.

Ideal for operations that require maximum performance in wet conditions while maintaining clean, stable screening.

Material Selection: Which Steel Type?

-

Spring steel – standard for wire screens; best cost-to-durability balance for everyday work.

-

Stainless steel – for wet/corrosive environments (wet sand, salt exposure, chemicals).

-

Heat-resistant steel – for high-temperature processes (e.g., asphalt plants).

-

Polymers (polyurethane/rubber) – when impact absorption, low noise, and long service life are required.

Quick Comparison Table

| Type | Pros | Cons | Best Applications |

|---|---|---|---|

| Woven wire | Low cost, high open area, accurate sizing | Wears faster, blinds when wet | Dry sand, gravel, fine fractions |

| Welded | Very rigid, stable geometry | Heavy, less flexible | Coarse fractions, high loads |

| Perforated | Impact resistant, durable | Lower throughput, heavy | Primary scalping, sticky/coarse feed |

| Harp | Self-cleaning, high capacity | Low impact resistance | Wet or clay-rich materials |

| PU/Rubber | Long-lasting, quiet, modular | Costly, lower open area | Heavy-duty, impact materials |

| Self-cleaning | Fewer stoppages, stable flow | Higher cost | Problematic/wet feed |

How to Choose? Practical Criteria

-

Material type:

Dry/clean → woven;

Wet/sticky → harp or self-cleaning;

Coarse/impact → perforated or rubber. -

Required throughput:

Higher throughput → high open area (woven/harp).

For longevity → PU or rubber. -

Sizing precision:

“Clean” fractions → smaller apertures and precise wire diameter. -

Working conditions:

Temperature, moisture, corrosion, noise limits → stainless, heat-resistant, or PU. -

Maintenance:

PU/rubber reduce downtime;

Wire screens cheaper but replaced more often.

FAQ

Which screen is best for wet sand?

Harp (stringer) or self-cleaning screens—they clog less. For longest lifespan, choose polyurethane modules.

When to choose perforated plates?

For primary scalping, coarse or impact materials requiring maximum strength and stability.

Are polyurethane screens always better than wire?

Not always. PU/rubber last longer and reduce noise, but have lower open area and higher cost.

For dry fine fractions, woven wire remains very effective.

How to know it’s time to replace the screen?

Falling throughput, inconsistent fractions, cracks, elongated apertures, frequent blinding—all clear signs.

Conclusions & Advice

If throughput and sizing accuracy are key → choose woven wire.

If you need durability and impact resistance → welded or perforated plates.

For wet and sticky materials → harp or self-cleaning screens.

For long lifespan and low noise → polyurethane or rubber modules.

Properly chosen screening media means fewer shutdowns, lower operating costs, and cleaner final fractions.

If unsure, test two types on different deck zones—for example:

Top deck → durable (perforated/PU)

Bottom deck → high open area (wire/harp) for maximum finishing efficiency.