How to Choose the Right Vibratory Plate Compactor?

A properly selected vibratory plate compactor is the guarantee of efficient and high-quality compaction of soil, gravel, or asphalt. The wrong choice can lead not only to poor results but also to higher costs, workflow interruptions, or even defects on site. How do you choose the vibratory plate compactor that best fits your project? In this article, we briefly and clearly review the main types of vibratory plate compactors, their applications, pros and cons, and give examples of Ammann models.

Main Types of Vibratory Plate Compactors

Vibratory plate compactors are classified by movement type and operating technology. Each type has its own advantages and is suited for different tasks.

- Forward Moving Vibratory Plates (APF series)

When to choose?

- If you are wondering how to choose a vibratory plate compactor for paving, light soil, sidewalks, we recommend single-direction Ammann APF series plates.

- Ideal for simple, quick, and versatile compaction in small areas.

How do they work?

- The vibratory plate compactor moves only forward, usually with a lower weight (about 50–100 kg).

- Easy to operate, often available with a water system (for asphalt) and a rubber/vulcolan pad (for pavers). This is an accessory designed for laying and leveling pavers. The vulcolan pad is made of hard rubber or semi-hard plastic, protecting pavers from scratches and damage during compaction.

Pros:

-

Lightweight and maneuverable

-

Perfect for small or finishing jobs

-

Simple maintenance, low operating cost

-

Easy to transport

Cons:

-

Not suitable for deep or heavy-duty compaction

-

Moves only forward – less effective on larger areas

Model examples (Ammann):

- APF 15/40, APF 15/50, APF 20/50, eAPF 12/40 (electric)

- Reversible Vibratory Plate Compactors (APR series)

When to choose?

- Excellent for larger areas when you need to move both forward and backward – for gravel, soil compaction, larger sites.

- Effective when you need more power and deeper compaction.

How do they work?

- The vibratory plate compactor can move both forward and backward, allowing faster and more convenient work, especially in narrow or complex areas.

- Usually heavier (from 100 up to 500 kg).

Pros:

-

Can compact thicker layers

-

Convenient control on larger areas

-

Higher productivity

-

Effective for both soil and gravel

Cons:

-

Heavier, requires more physical effort for transport

-

More expensive than single-direction plates

Model examples (Ammann):

- APR 25/50, APR 30/50, APR 40/60, APR 52/75, APR 59/20, eAPR 20/40

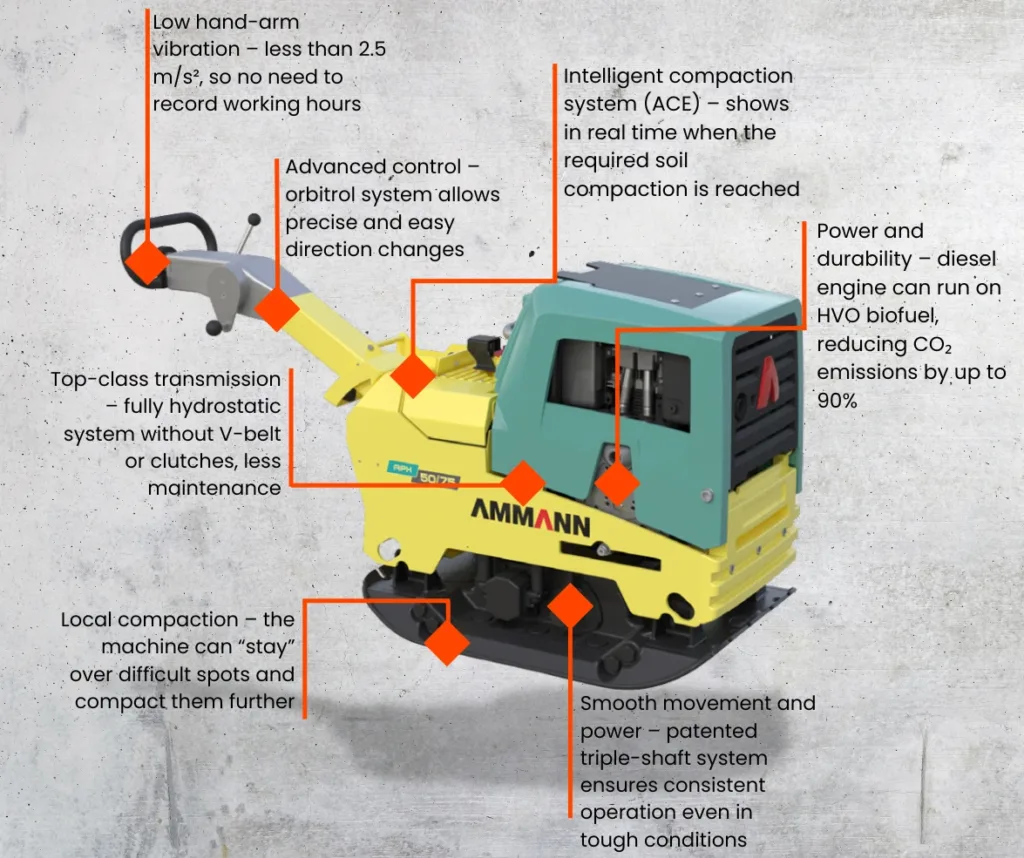

- Hydrostatic Vibratory Plate Compactors (APH series)

When to choose?

- For large construction sites and professional contractors needing maximum productivity, strong compaction force, and efficiency on large-scale or industrial sites.

Kaip veikia?

- Hidrostatinė pavara, vibraciją generuoja trigubo veleno (triple-shaft) technologija – labai stabili eiga, mažai vibracijos perduodama operatoriui.

- Galima ACE (Ammann Compaction Expert) sistema – automatinis tankinimo kontrolės matavimas.

How do they work?

Hydrostatic drive, vibration is generated by triple-shaft technology – very stable movement, minimal vibration transferred to the operator.

Can be equipped with the ACE (Ammann Compaction Expert) system – automatic compaction control.

Pros:

-

Highest vibration force and depth – works with the thickest layers

-

Extremely stable movement, comfortable control, effective even on slopes and wet ground

-

Automatic compaction control (ACE)

-

Lower fuel consumption, reliable operation

Cons:

-

These are the heaviest and largest vibratory plate compactors – limited mobility without additional transport equipment

-

The most expensive type of vibratory plates

Model examples (Ammann):

APH 50/75, APH 60/85, APH 65/85, APH 85/95, APH 110-95, eAPH 70/95

- Electric Vibratory Plate Compactors (eAPF, eAPR, eAPH series)

When to choose?

For indoor work, city centers, where zero emissions and reduced noise are required.

Ideal when you need lower operating costs, simple maintenance, and operation.

How do they work?

Instead of an internal combustion engine – an electric motor with a battery.

Both single-direction, reversible, and hydrostatic versions are available.

Pros:

-

Zero emissions – environmentally and operator friendly

-

Quiet operation, can be used in sensitive areas

-

Lower operating costs (no fuel required)

Cons:

-

Limited working time (battery life) – depends on battery capacity and charge

-

Higher price

Model examples (Ammann):

eAPF 12/40, eAPF 12/50, eAPR 20/40, eAPH 70/95

For more information about all Ammann vibratory plate compactor models, their technical data, and innovations, visit the official Ammann website.

Additional Features and Innovations (Ammann)

-

ACE system: Automatic compaction efficiency measurement (especially for APH series)

-

Water system: Asphalt vibratory plates with integrated water sprinkler

-

Rubber mat: For pavers, protects the surface from damage

-

Ergonomic, anti-vibration handles: For greater comfort and safety

-

Quick-change system: Easy pad/screen replacement

-

How to Choose a Vibratory Plate Compactor? – Practical Checklist

-

Small-scale, light work, paving, narrow sidewalks?

→ Forward moving vibratory plate compactor (APF series) -

Larger areas, deep compaction, more difficult or mixed materials?

→ Reversible vibratory plate compactor (APR series) -

Large-scale, industrial sites, especially thick layers or slopes?

→ Hydrostatic vibratory plate compactor (APH series) -

Indoor work, city, sensitive environments?

→ Electric vibratory plate compactor (eAPF, eAPR, eAPH) -

Very large areas, especially thick soil layers, industrial sites or roads?

→ In these cases, a roller is often recommended for highest productivity and compaction efficiency.

Read more about the advantages and selection of different rollers in our guide about the rollers. -

Practical Examples

-

Paving, narrow sidewalks:

APF 15/50 with rubber mat

(alternatives: Bomag BP 12/50, Wacker Neuson VP1550, Husqvarna LF 60) -

Coarse soil, base layer compaction:

APR 40/60 reversible vibratory plate

(alternatives: Bomag BPR 45/55 D, Wacker Neuson DPU 4545, Weber CR 6) -

Industrial yard, thick base layer, need for stability:

APH 65/85 with ACE system

(alternatives: Bomag BPH 80/65S, Wacker Neuson DPU 6555, Swepac FB 465) -

Noise-sensitive area, indoor use:

eAPF 12/40 electric vibratory plate compactor

(alternatives: Wacker Neuson AP1840e, Weber CF 2 E, Husqvarna LG 204E)

Conclusions and Recommendations

Choosing the right vibratory plate compactor ensures efficient, fast, and high-quality compaction – smoother workflow, higher quality, longer pavement life.

Still not sure how to choose a vibratory plate compactor? Contact Erco Technologies – we will help you find the optimal solution for your needs!