How to Choose the Right Roller? The Differences Between Soil, Asphalt, and Pneumatic Rollers

Knowing how to choose a roller is crucial for any construction or road-building project. The right decision ensures strong foundations, while the wrong one can lead to costly mistakes and delays. The market offers a wide variety of models, so how do you navigate them all? In this guide, we, the experts at Erco Technologies, will explain the key differences between soil, asphalt, and pneumatic rollers to help you make the best choice.

How to Choose a Roller: Understanding the 3 Main Types

Although all rollers perform the same basic function – compacting a surface – their design and operating principles are adapted for very different materials and jobs. The main types you will encounter are:

1. Soil Rollers (Single-Drum Vibratory Rollers)

2. Asphalt Rollers (Tandem Vibratory Rollers)

Let’s examine each of them in more detail.

1. Soil Rollers: Power and Weight for Foundations

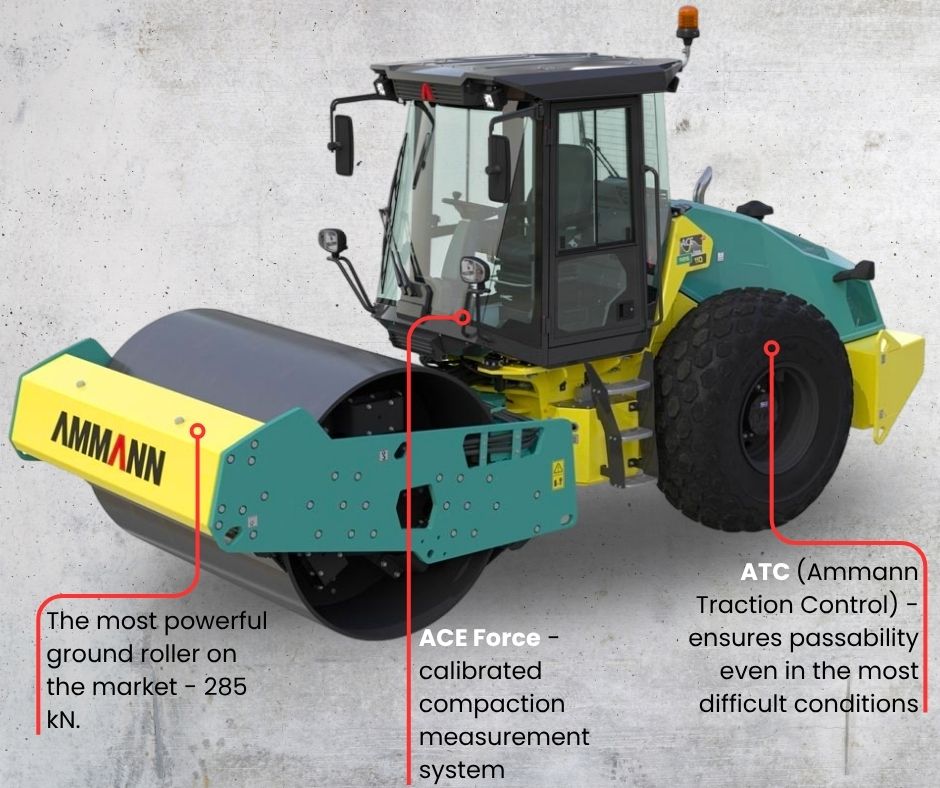

[Image: A powerful Ammann ARS soil roller working on a large construction site. ALT text: How to choose a soil roller for sub-base compaction.]

When to choose one? A soil roller is your first choice when you need to compact large areas of soil, sand, gravel, or aggregates. It is indispensable when constructing road sub-bases, foundations for industrial buildings, parking lots, or laying railways.

Key features: This type of roller has one large, smooth, or padfoot (for cohesive soils) vibratory drum at the front and large tires at the back. Due to their heavy weight and a powerful vibration system with high amplitude, they can effectively compact soil in thick layers. We recommend choosing soil rollers with compaction meters, which allow you to see the compaction results and save fuel once the required parameters are met.

Example: For this task, the Ammann ARS 110 or ARS 130 models from our range are ideal, known for their high performance and reliability. We recommend the “smart” ARS 110 ACEpro soil roller with automatic vibration, which allows for more uniform compaction.

2. Asphalt Rollers (Tandems): Precision and Smoothness

[Image: An Ammann ARP tandem roller working on fresh asphalt. ALT text: Choosing a tandem roller for smooth asphalt surfaces.]

When to choose one? When the sub-base is prepared and paving work begins, the tandem asphalt roller rolls onto the site. Its main task is to properly compact the asphalt pavement, ensuring its smoothness, density, durability, and resistance to loads.

Key features: Tandem rollers have two smooth steel drums (one at the front, one at the back), both of which are usually vibratory. They are lighter and more maneuverable than soil rollers. An essential feature is the integrated water-sprinkling system, which prevents hot asphalt from sticking to the drums. Modern models, like the Ammann ARP 75, have split drums that protect the fresh asphalt from tearing during turns.

We recommend “smart” tandem rollers like the ARP 75 with ACEpro, which automatically selects the necessary compaction parameters (vibration amplitude, frequency) and adjusts them until the target is reached.

3. Pneumatic Tyred Rollers: Finishing Touches and Sealing

[Image: An Ammann ART pneumatic roller sealing a new asphalt road. ALT text: How to choose a pneumatic roller for final compaction.]

When to choose one? The first application is for compacting the frost-resistant layer of the road structure (sand sub-bases). They effectively compress the material and achieve the required compaction result. We recommend choosing models with enhanced traction, such as the Ammann ART240 with the ATC (Ammann Traction Control) system.

The second application for a pneumatic tyred roller is in the final stage of asphalt pavement compaction. Its purpose is to “knead” and hermetically seal the pores of the asphalt surface, ensuring the pavement’s resistance to water and improving grip.

Key features: Instead of steel drums, these rollers have a row of rubber tires. Their weight can be adjusted by adding ballast (water or metal). The kneading action and heat from the tires help to form a seamless and durable surface.

Example: Our offered Ammann ART 240 is an excellent example of this type of roller, featuring modern systems like tire pressure adjustment and ATC.

Three Key Questions to Ask Before Choosing a Roller

To make the final decision, answer these questions:

1. What material will I be compacting?

- Soil, sand, gravel, aggregates: You need a powerful soil roller. If the soil is cohesive, look for a model with padfoot segments.

- Asphalt: You will need at least two rollers. For the initial and main compaction, a lighter and a heavier asphalt roller (tandem) are needed. The number of rollers should be chosen based on the width of the asphalt layer being paved to ensure timely compaction before the temperature drops below 100°C.

2. What is the size and nature of the project?

- Large, open areas (highways, industrial zones): Choose heavier and wider rollers, e.g., 10-13 ton soil rollers (Ammann ARS 110/130) or heavier asphalt rollers (Ammann ARP75/95 or even ARX140/160). This will ensure maximum productivity.

- Small to medium-sized projects (city streets, parking lots, landscaping): Mid-class rollers are perfect, e.g., Ammann ARS 70 for sub-base work, and ARX45-2 or ARP75 for asphalt.

- Confined spaces (sidewalks, bike paths, trench backfilling): Small, compact, and maneuverable ARX series tandems are required (e.g., 1.5-4 ton rollers for asphalt).

3. What are the compaction quality requirements?

- Standard requirements: For many projects, standard equipment will suffice. Compaction requirements are defined by regulations, and all Ammann rollers with compaction meters are factory-calibrated to show the compaction level in MN/m.

- Highest requirements: If the project has particularly strict compaction requirements, such as for highways, it’s important to optimize the process. Look for rollers with intelligent compaction systems like Ammann ACEforce or ACE Pro. They help prevent defects, save time, and reduce fuel consumption.

Conclusion

Choosing the right roller is an investment that saves time, reduces costs, and guarantees a high-quality final result. Whether you need a powerful soil compactor for foundations or a precision asphalt roller for city streets, the key is to understand their differences and apply the right tool for the specific job, as also recommended by authoritative sources in the construction industry.